Manufacturing & Quality Control Facilities

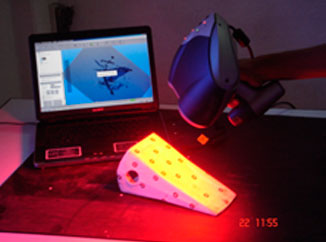

3D Scanner

Handheld 3D Laser Scanner Used for 3D Scanning, 3D Modeling, Inspection, Reverse Engineering.

Simulation Software

Finit Element Method Solidification, Simulation of various processes to help to get product for faster development.

Heat Treatment

Continuous Heat Treatment and Batch Type Bogie Furnaces

Physical Testing

Impact Testing Machine

Universal Testing Machine

Melting

Induction Melting Furnaces with production capacity of 9000 tons / annum

1 Kg to 800 Kg / Piece

Spectro Meter

22 Chanels

18 Elements

MPI Machine

Crack Detection

Non-Destructive Testing

Radiography Testing

Dark Room

R.T. Film Viewer

Facilities at Mayura Steel Pvt. Ltd Unit 1

| Melting | : | Induction furnace of 600 Kgs. capacity (2 pots) |

| Dip type pyrometer (1700°C) | ||

| Moulding | : | Wesman continuous sand mixer - 3 tons/ hour |

| Jolt squeeze machine table 24"' x 16" | ||

| Sand Muller - 300 Kgs. batch | ||

| Knock out machine - 5 tons / hr. | ||

| Core shop | : | Susha make shell core shooter |

| Core oven (350°C) | ||

| Compax CO2 core shooter | ||

| Shell core shooter dump box | ||

| Heat Treatment | : | Centralised Computerised Control System |

| Oil fired furnace 1500 Kgs. capacity - 2 Nos. | ||

| Oil fired furnace 1000 Kgs. capacity - 1 No. | ||

| Quenching tanks with agitation & cooling system (& water 12000 lit.) | ||

| Ctric Bogie Type Furnace (Tempering) | ||

| Fettling | : | Shot blasting machine (500 Kgs.) - 1 No. |

| Pedestal grinder with 14 " & 16 " wheel | ||

| Swing frame 16 " & 12 " wheel grinders | ||

| Plasma cutting machine | ||

| DC welding machine & DC generator |

Facilities at Mayura Steel Pvt. Ltd Unit 2

| Melting | : | Induction furnace of 900 Kgs. capacity (2 pots) |

| Dip type pyrometer (1700° C) | ||

| Land Make Temperature Meter | ||

| Moulding | : | Omega continuous sand mixer - 5 tons/ hour |

| Jolt sqeeze machine table 24" x 16" | ||

| Sand muller - 300 Kgs. Batch | ||

| Sand Reclaimation , Knock out machine - 5 tons / hr. | ||

| Core shop | : | Susha make shell core shooter |

| Core oven (350°C) | ||

| Compax CO2 core shooter | ||

| Shell core shooter dump box | ||

| Heat Treatment | : | Centralised Computerised Control System |

| Oil fired furnace 1500 Kgs. capacity - 4 Nos. | ||

| Quenching tanks with agitation & cooling system (Oil 2000 lit. & water 15000 lit.) | ||

| Continuous Heat Treatment Furnace 500 kg/hour | ||

| Fettling | : | Shot blasting machine (500 Kgs.) |

| Pedestal grinder with 14" & 16" wheel | ||

| Swing frame 16" & 12" wheel grinders | ||

| Plasma cutting machine | ||

| DC welding machine & DC generator |